Certificates

Here we are going to explain how to manufacture appalam in mahaganapathi foods step by step process. (appalam and papad manufacturer in Madurai, Tamilnadu, India.) Appalam is a thin crispy round snack from south india. It is typically based on a seasoned dough usually made from pealed black gram flour (Urad dal flour).

It is typically served as an accompaniment to meal. It has many names depending upon the geography these are, it called as Handmade Appalam, Popadam, Appalam, Papadum, Appadam, Puppodum, Pampad Happala, Popadoms, Paparis , Poppadam, Urad Dal Papad, Papad, Poppadom, Pappad, Pappadam, Papads, Poppadum, Papadam, Papadom, Pappadum.

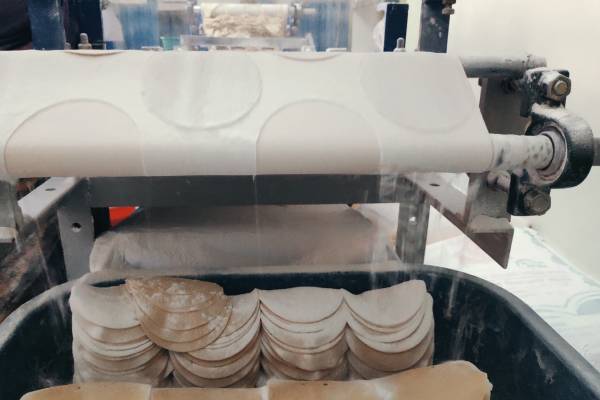

Sheeting is one of the most important steps in appalam manufacturing . It makes the dough soft. Also makes the appalam expand while deep frying it. Once we send dough through the sheeting machine, the dough become softer. Now the dough sheet is ready, sent to appalam / papad making machine.

The sheets of dough are coated with oil on both sides. This prevents the dough from sticking to the thinning roller. Once the sheet of dough is sent through thinning roller, the thickness of the sheet is reduced from 1 or 1.5 inch to 0.5mm. This will be the final thickness of the appalam.

This sheet of dough will be sent through cutting roller which will cut in a specified dimension (3”, 3.5”, 4”, 4.5”, 5”, 5.5”, 6” inch) and shape. The appalams coming out of the roller will be stacked on top of one another. Powdered rice flour will be coated between each appalams to avoid stickiness in a stack.

Now, the appalams which are cut in shapes are stored in room temperature for 7 hours for fermentation. This plays a major role in expansion of the appalams while it is deep fried.

Drying process take two days.

Once the fermentation is done, each appalam is dried under direct sunligh for 30min in day 1 process. After that collect all half dried appalams and store it in a rakes.

Which is the final process here half dried appalams are dried for 15mins. collect it and store now, we can get our tasty appalams and is ready to pack.

The same ingredients are taken for preparing hand made appalam. But the process of manufacturing appalam without the machine. We do it in hand using a wooden roti/chapati maker.